P/N 8700 CNC 4" Rotary Table Indexer. (Click on image for a larger view)

CLICK HERE to view instructions for

|

The Advantages of a Computer-Controlled Rotary TableA computer controlled rotary table takes the headaches out of repetitive indexing operations. Sherline's new CNC rotary table is a stand-alone unit that includes everything you need to do accurate rotary indexing operations at the touch of a button. Included in the package is the rotary table, mounted stepper motor with preloaded and dampened coupling, power supply, computer/keypad unit, connecting cables, mounting hardware and detailed instructions. Clever design and programming by Bryan Mumford at Mumford Micro Systems has yielded a package that offers you the functions of popular industrial CNC indexers at a fraction of the cost. Priced within the reach of the home shop machinist, this table can also be used by small shops and in an industrial production setting*. It can be used on Sherline milling machines or on full-size machines. In production settings, it can be configured to operate as a stand-alone unit or it may be integrated to work in conjunction with other CNC controllers. *In a production environment, the stepper motor cannot be flooded with coolant and the control unit should be shielded from hot chips as well as coolant. Resolution and Backlash CompensationThe 100 oz-in stepper motor has a resolution of 400 steps/rev., which, when coupled to the rotary table's worm gear drive, divides a circle into 28,800 steps (±.006°/step). Rotation speed is programmable from 1°/sec to 50°/sec. Once the worm gear backlash is mechanically adjusted to a minimum amount, the remaining backlash can be compensated for electronically so that the table can be advanced and then returned to previous settings with a high degree of accuracy. Back to top |

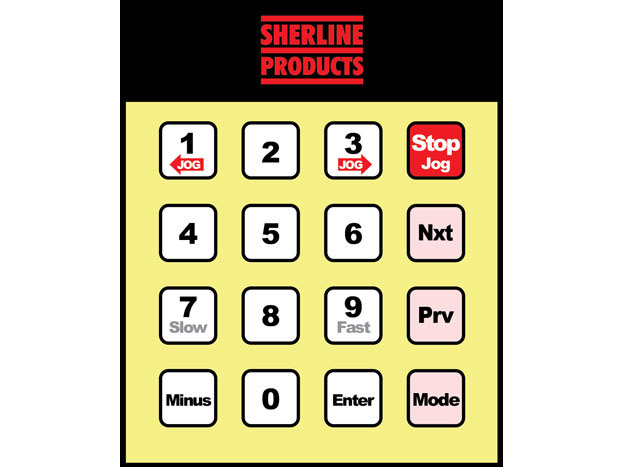

All entries are made from this simple keypad. No separate computer is needed. (Click on image for a larger view) |

Modes of OperationThere are five modes of operation. A circle can be divided into steps by either degrees or divisions of a circle. A push of the [NXT] button advances the table to the next position. The [PRV] button can be used to recall previous settings. In the "Jog" mode, the table can be moved in individual steps or in rapid, continuous motion in either direction. A handwheel calibrated in 1/10° increments also allows accurate manual positioning of the table. The built-in memory of the computer has room for two separate user-settable programs of 40 sequenced operations each. Parameters for each operation such as speed, direction and whether or not the unit waits for a command to continue can be left in the default mode or changed for any single operation. Using the Unit with other CNC ControllersAn 8-pin mini-DIN connector allows the unit to accept "step" and "direction" signals for use with other motor controllers. It also accepts "sense" and "acknowledge" signals from handshaking with other CNC controllers. Back to top |

The above illustration shows P/N 8710 CNC Rotary Indexer Riser Plate in place. (Click on image for a larger view) |

Use of a Spacer BlockWhen using this rotary indexer on a model 5400, model 2000 or any CNC Sherline mill, some setups will require the use of a riser plate to prevent interference with the Y-axis handwheel or stepper motor. Sherline offers a spacer block (P/N 8710) that raises the rotary table 1/2", eliminating any interference. Sherline's tilting angle table (P/N 3750) can also be used for this purpose as well as to mount the indexer at any angle from 0° to 90° to the table surface. The P/N 8710 spacer block can be mounted to a mill table or held in a vise to facilitate the mounting of the rotary indexer. Plans detailing the size and hole pattern of this simple block are included with the rotary indexer instructions in case you prefer to make your own. Features

Back to top |

Search Our Site